|

BELSORP MAX X

A lot of Science in a little space: BELSORP MAX X. High-End Adsorption. Smallest Footprint. Unrivaled Performance.

Microtrac MRB's BELSORP MAX X is the latest model in the BELSORP MAX series, featuring a more compact design and lower weight.

This high-precision gas / vapor adsorption analyzer can measure up to four samples over a wide range of pressures and temperatures.

BELSORP MAX X covers a broad array of analysis capabilities from specific surface area, pore size distribution, gas, and vapor adsorption to chemisorption.

Combining high-precision pressure transducers (133.3 kPa, 1.333 kPa, and 0.0133 kPa) with hard-sealing pneumatic valves and

metal gaskets, the analyzer has superior technology to minimize gas leakage and enable ultimate vacuum levels.

Temperature in the BELSORP MAX X is carefully controlled using state-of-the-art technology, from the heated manifold block

(50 °C, optional 80 °C) and air bath to the sample, while electropolished gas / vapor lines prevent surface wetting and corrosion.

Additionally, the new BELCONTROL operation software facilitates understanding of the structure and durability of materials through cyclical stability analysis,

improves measurement and maintenance efficiency, and sends measurement results via e-mail – all resulting in maxXimized sample throughput.

BELMASTER is the dedicated analysis software for advanced material evaluations.

This instrument complies with ISO 9277, 15901-2 and 18852 and can be used for various material morphologies, such as molded bodies, pellets, and fine powders.

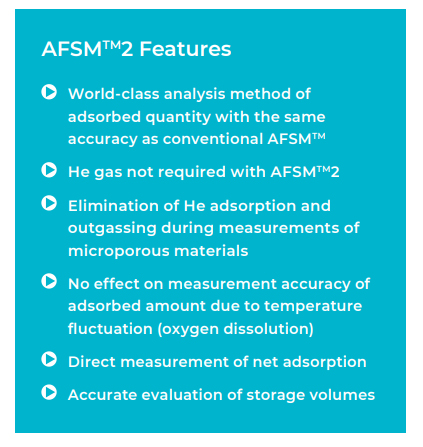

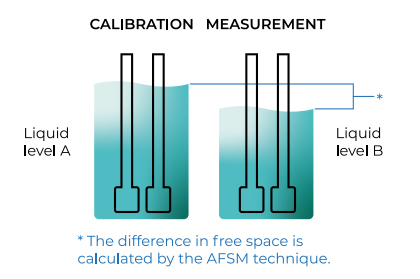

AFSM2 - Helium free, short time measurement!

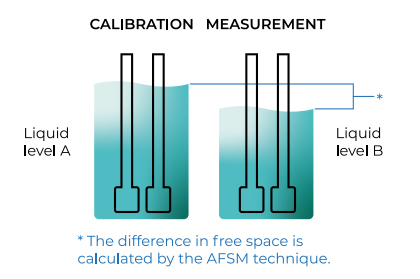

Measurement techniques for determining free space often use calculated values of free space

at both room temperature and measurement temperature of each sample tube (including

the volume reduction filling rod and filter) and the true density of the sample.

With the new technique “AFSMTM2”, although the liquid level is not always the same during

calibration and measurement (liquid levels A and B in the figure), the change in free space is

the same for both conditions. This new meth�od takes advantage of a highly reproducible

AFSM and free space determination that elim�inates the need for He gas.

This makes it pos�sible to obtain the highest repeatability in the world without the need for He gas.

Specifications

|

Measurement principle |

Constant volumetric method + AFSM™ |

|

Adsorption gas |

N2, Ar, Kr, CO2, H2, O2, CH4, NH3, and other non-corrosive gases |

|

Adsorption vapor |

H2O, MeOH, EtOH, C6H6, and other non-corrosive vapor |

|

Gas ports |

3 ports (optional: up to 12 ports) |

|

Number of measurements |

Max. 4 ports simultaneously |

|

Measurement range (specific surface) |

0.01 m2/g and above (N2)

0.0005 m2/g and above (Kr)

(depending on sample density) |

|

Measurement range (pore size distribution) |

0.35 - 500 nm (from 0.25 nm when CO2 is used) |

|

Measurement range (vapor adsorption isotherm) |

p/p0 = ~0.95 @40°C |

|

Pressure transducer (133 kPa: 1000 Torr) |

Max. 6 units |

|

Pressure transducer (1.33 kPa: 10 Torr) |

Max. 4 units |

|

Pressure transducer (0.0133 kPa: 0.1 Torr) |

Max. 3 units |

|

Thermostatic air oven |

50°C |

|

Vacuum gauge / pump |

Turbo molecular pump + rotary pump |

|

Measurement temperature (Dewar vessel) |

LN2, LAr temperature; Holding time: 80 h |

|

Measurement temperature (Pretreatment heater) |

50 - 550°C |

|

Measurement temperature (Water bath) |

-10 - 70°C (constant temperature circulator) |

|

Dimensions (W x H x D) |

360 x 870 x 590 mm |

|

Weight (main body) |

50 kg |

|

Utility - Gas |

He, adsorption gas: 0.1MPa

Joint: 1/8" Swagelok joint

Valve drive gas: 0.5 - 0.6 MPa

1/4" one-touch pipe contact |

|

Utility - Power |

AC 100 - 240 V or less (rotary pump not included) |

|

CE certified |

yes |

|

Operating software |

Windows 10 operating system or higher, CPU Intel(R) Core i5 or higher

2 GB of memory or more, 5 GB HDD space or more |

|

Recommended Monitor |

Full HD monitors | |