|

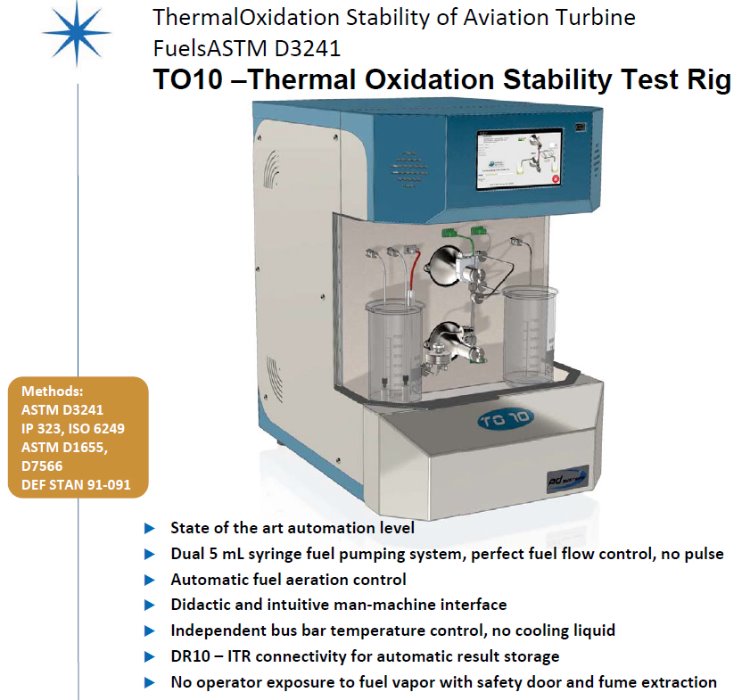

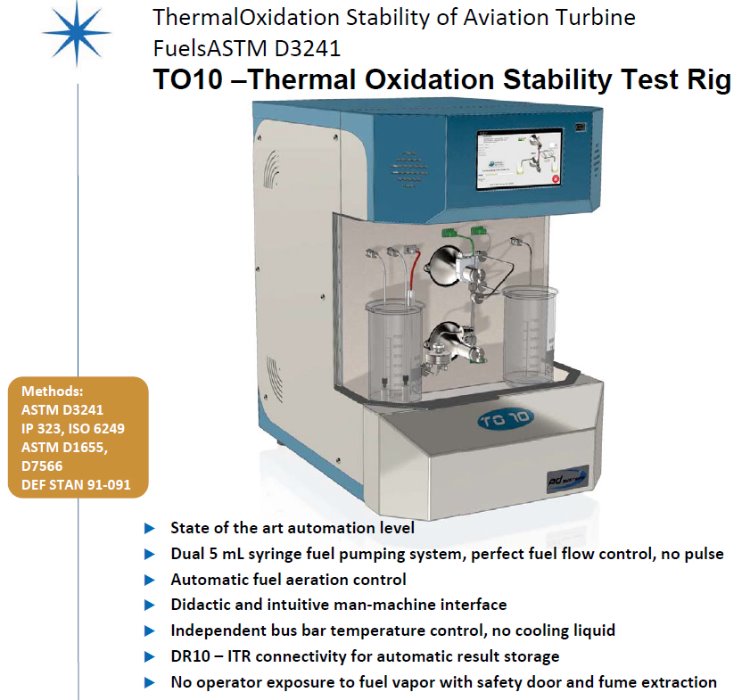

TO10

The ASTM D3241 / IP 323 Thermal Stability test is one of the most important tests for the jet fuel quality. This test method was inherently limited due to the subjectivity in the color standard for tube deposit rating

Recently advanced testing metrics (called metrological method) for quantifying the thermal stability characteristics of jet fuels was declared the referee technique by jet fuel specification bodies.

This new approach highlighted the weaknesses of the existing thermal jet fuel oxidation test rigs. By precisely mapping the thermal oxidation deposit on the surface of the aluminum tube, it became possible to identify issues with existing test rigs that were undetectable with the visual (VTR) rating.

Based on these finding, AD Systems developed a new jet fuel thermal oxidation test rig (TO10) that ensures perfect fuel preparation, perfect fuel flow control, a perfect heater tube temperature profile and perfect thermal deposit quantification with the Deposit Rater - DR10.

Methods

For the development of this innovative instrument, all the parameters influencing the accuracy of the D3241 / IP323 test method have been identified. For each of these parameters an innovative and reliable solution has been developed. This very successful apparatus is unmatched in the market

The preparation of the test is simplified. No tools are needed for assembly and the heating tube mounting. An extremely intuitive teaching software makes it possible to very quickly initiate a test and if necessary to follow step by step its progress.

- ASTM D3241

- ASTM D1655

- ASTM D7566

- IP 323

- ISO 6249

- DEF STAN 91-091

Application

Based on its flexibility, its robustness and reliability, the TO10 is designed for any type of applications, research, civilian and military fuel certification.

Benefits

State of the art automation level

Dual 5 mL syringe fuel pumping system, perfect fuel flow control, no pulse

Automatic fuel aeration control

Didactic and intuitive man-machine interface

Independant bus bar temperature control, no cooling liquid

DR10 - ITR connectivity for automatic result storage

No operator exposure to fuel vapor with safety door and fume extraction

Specification

Test method

ASTM D3241, IP 323, ISO 6249

Up to 21 programmable test methods

Test Temperature

Programmable from 100°C up to 380°C

Differential Pressure

0 – 750 mmHg (automatically bypassed at +700 mmHg)

Test time Range

Programmable from 4 to 600 minutes

Fuel Aeration

Programmable time, automatic air flow control

Aeration Flow rate

Programmable or according to test method, 1.5 L / min

Air Flow Humidity

Humidity sensor with displayed message for dessicant replacement

Heater tube temperature measurement

Thermocouple Type K, class 1

Fuel Flow

Dual 5 mL syringe, maintenance free, programmable fuel flow rate or according to test method

Accuracy ±1%

No flow pulse or peak

Bus Bar Temperature Control

Independent and programmable, each bus bar temperature can be adjusted

No liquid cooling circulation

Peltier modules + heat pipe technology

Heater tube section assembling

Special gauge to quickly and perfectly position the heater tube

Fuel vapor handling

Dedicated compartment with sliding doors acting like fume hood encompassing

beakers and heater tube section, connectable to a fume extractor

Diagnostic and Service

Dedicated service menu with a flow chart layout with ability to click on each

symbolic element to check its operation

DR10 – ITR connectivity

Via Ethernet port RJ45

Full test results can be automatically transferred from the DR10 to the TO10

Results storage

Result database

Limited only to capacity of external device

LAN connectivity

Ethernet port RJ45

Printer output

USB (printer is optional)

Data output

USB (2), Ethernet

Dimensions(mm)

440 x 600 x 670

(17”x 23”x 26”)

Weight

60 kg (133lbs.)

Electrical

100 to 240V - 8 A - 50/60 Hz

Operating temperature

From +10 to +35°C

Relative humidity

20% to 90% non-condensing |