|

Working principle XPT-C: particle supsension is pumped through the flow-through cell on the outside of the unit - either directly from a process or from a sample. A CCD camera continuously takes images which are analysed in real time, results displayed and saved.

Complete system: consists of stainless steel housing with camera and lighting system by xenon flash or high-power LED, flow-through cell, peristaltic pump, magnetic stirrer, controll system, PC and software.

Measurement range: from 1 micron upwards, maximum resolution 0.3 micron/Pixel

Technical data:

Minimum sample size: 1ml

Housing dimensions 380 x 300 x 120mm

Material: stainless steel

Power supply 115/230V, optional 12V rechargeable battery

Applications:

Particles, droplets or bubbles in liquid

Measurement of particle size, shape and count

Particle shape detection

High pressure / high temperature

Adhesives, epoxy resins

Counting product beads into vials

Detection of micrometer particles in highly concentrated submicron dispersions

Particles in hot engine oil online under pressure

Counting of fibres in other particle suspension

Tracking Osswald ripening of crytall needles

Measurement of shape change of grinding particles

Food, pharma, polymers, chemicals, oils...

Bubbles in soda and beer or bubblefree measurement under pressure

Yeast cells in wheat beer

Shaving foam, whipped cream

New options !:

Heated flow-through cell for measurement in melts

Polarized light for online discrimination of amorphous and crystalline particles

Software:

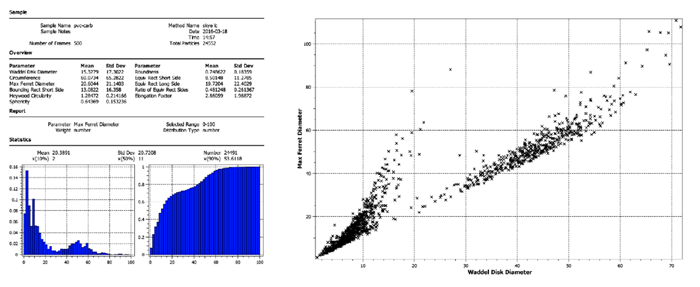

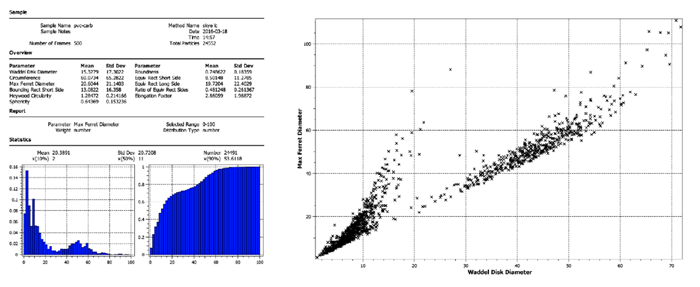

• All options are measured, all reports are done after the measruement

• Particle size distribution, scatter-plot, trends over time

• Diameter, length, shape factors

• Optional simultaneous storage of the measurement as movie

• Analog output with measurement results for online measurement

• Analysis of live images or stored images or movies

|