|

A new Iludest distillation plant extends the limits of what is possible and

enables the extremely pure separation of bitumen fractions in a packed

distillation column — In this way the process engineers from Waldbüttelbrunn

defy the thermodynamic limits of the ASTM Standards D2892 and

D5236, and bring two seemingly incompatible requirements under one hat.

Bitumen fractions with challenging boiling requirements and characterized by low

overlapping fractions require a high separation capacity of the columns and high

temperatures that can be achieved only under high vacuum conditions. “These are

conditions which cannot be satisfied so far with the parameters specified by the

D2892 and D5236 standards”, says Dr.-Ing. Hans-Eckhard Koenen (Engineer), Team

Leader “Thermodynamics” at IIudest/i-Fischer. For the delivery of this

particular customer demand, the Waldbüttelbrunn Company who devised the solution

has received the “PROCESS Innovation Award” at Achema, the second within the

intervening period. The seven strong team of IIudest/i-Fischer engineers has

managed to reinvent distillation again and again. This time round, the Fischer

Autodest 800AC/HV has put the competition in its place. The special features of

the distillation plant are that this apparatus covers a temperature range which

extends the range of the ASTM Standards D2892 and D5236 still further—and that

too in a single packed column at a vacuum down to 10-3 Torr. The system therefore

exceeds the boiling point of the bitumen fraction, i.e., achieves a temperature

range of 560 to 600°C (equivalent to atmospheric pressure) This is clear if one

examines the thermodynamic definitions of the two standards more closely, and

this is what the team of engineers has actually done.

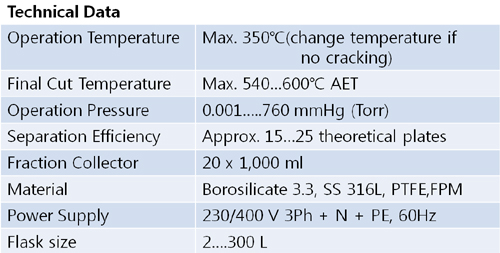

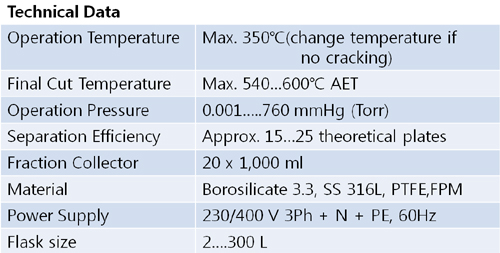

• ASTM D2892 is based on a packed column with a theoretical separation capacity of

15 theoretical plates, operated at a vacuum of 2 Torr and a boiling point of

400°C (at atmospheric pressure).

• In comparison ASTM D5236 is based on an open tubular column, a theoretical

separation capacity of 2 theoretical plates, operated at 0.1 Torr, with a maximum

boiling point range of 540 to 565°C (at atmospheric pressure).

On the crucial point of getting both standards under one hat, Koenen says: “High

separation capacities are possible only with packed columns, but high temperatures

are possible only with open tubular columns, because a deeper lower vacuum is

possible here.” In other words, if one wants to outsmart thermodynamics, one must

develop distillation units that can withstand a high vacuum, because lower process

temperatures are possible only at higher vacuum levels. Finally, the hydrocarbon

chains crack at above 300°C, a process which one must avoid during crude oil

distillation. The incentive for the development came from two customer requests,

which followed one after the other in brief succession. Meanwhile, the first

prototype is already in use at a German petrochemicals company, whose request had

initiated the development in the first place. The units installed there achieve a

temperature of 560°C atmospheric equivalent, which corresponds to an operating

vacuum of 0.1 Torr and achieve the theoretical separation capacity of 25

theoretical plates (also under vacuum). The winning Autodest 800AC/HV, which was

commissioned for a company in South Africa, tops in performance once again with a

maximum boiling point of 600°C atmospheric equivalent, and a separation capacity

of 30 theoretical plates. Such temperatures can be achieved only with a vacuum of

10-3 Torr, i.e., under the operating conditions of a short-cut path evaporator.

The challenge is described by Koenen and CEO Stefan Opis as follows:

“Thermodynami-cally, the requirements were mutually contradictory: The column

design requires a vacuum of 10-3 Torr and the fraction volumes required for the

separation capacity had to be bigger than the column hold-up volume.” If the

preceding order, which had paved the way for this requirement, had not come

through—who knows, perhaps the process engineers would have thrown in the towel.

“According to the available experience values, we knew that a column design was

possible”, says Koenen. The biggest challenge was the vacuum system. It became clear

to the process engineers rather fast that a normal oil diffusion pump would have

reached its limits. “We had to file the pipe sections and overcome turbulences

which would have caused a pressure fall drop”, explains Koenen. But the

calculations matched during the very first run, and the trial distillation was

successful.

|